PUR conservation creates efficient production procedures for PUR perfect binders

We are the inventor of the Best for PUR preservation unit.

- At least 4 x per week cleaning time becomes additional production time

Saving: € 12.000.- p.a.

- At least 4 x longer lifespan of the valuable non-stick-coating

Saving: € 4.000.- p.a.

- Saving up to 3 kg PUR adhesive waste daily

Saving: € 4.800.- p.a.

- Reducing chemical cleansing agents by 80%

Saving: € 400.- p.a.

- Free your employees from aggravating cleaning work

Saving: priceless

- The Best for PUR preservation unit increases your corporate profit and protects the environment

- Full flexibility for changes from PUR to EVA Hotmelt

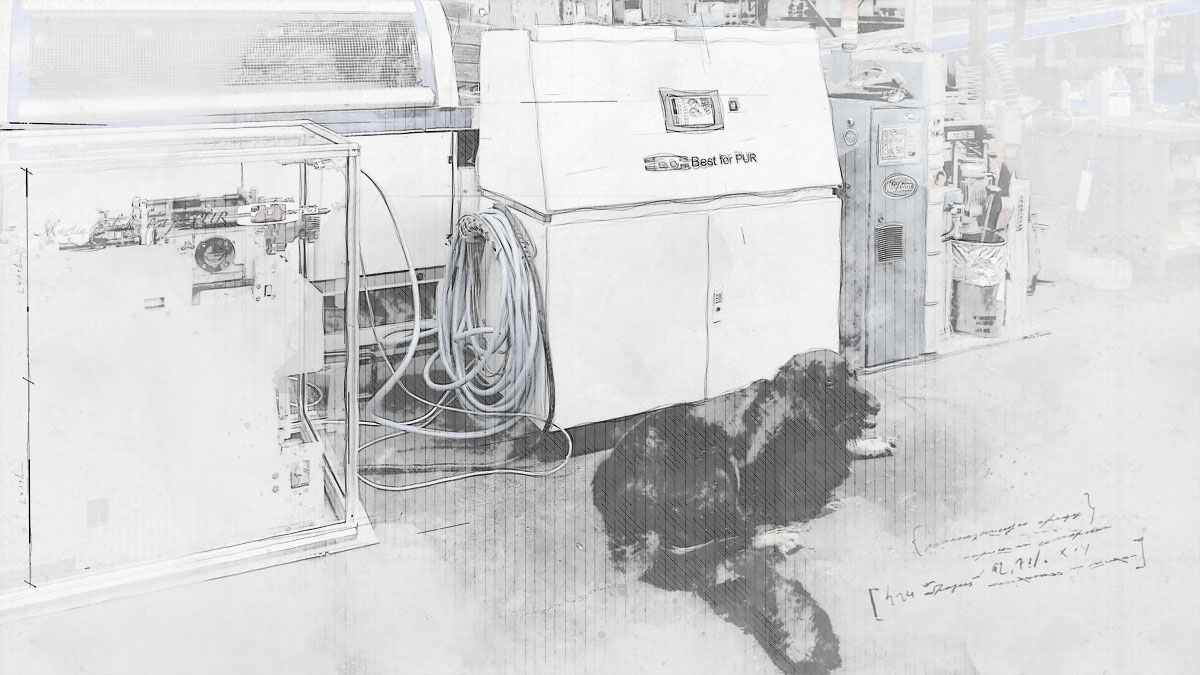

Choose from two different versions to meet the individual space conditions in your bookbindery:

Often, space is limited at the perfect binder.

Especially around the glue-trolley there might be little room due to circulating conveyor belts, walls or other machines. The standard hood needs barely more space than the pulled-out glue-trolley itself – the control cabinet may also be positioned further away. Let us know your situation – we are happy to advise.

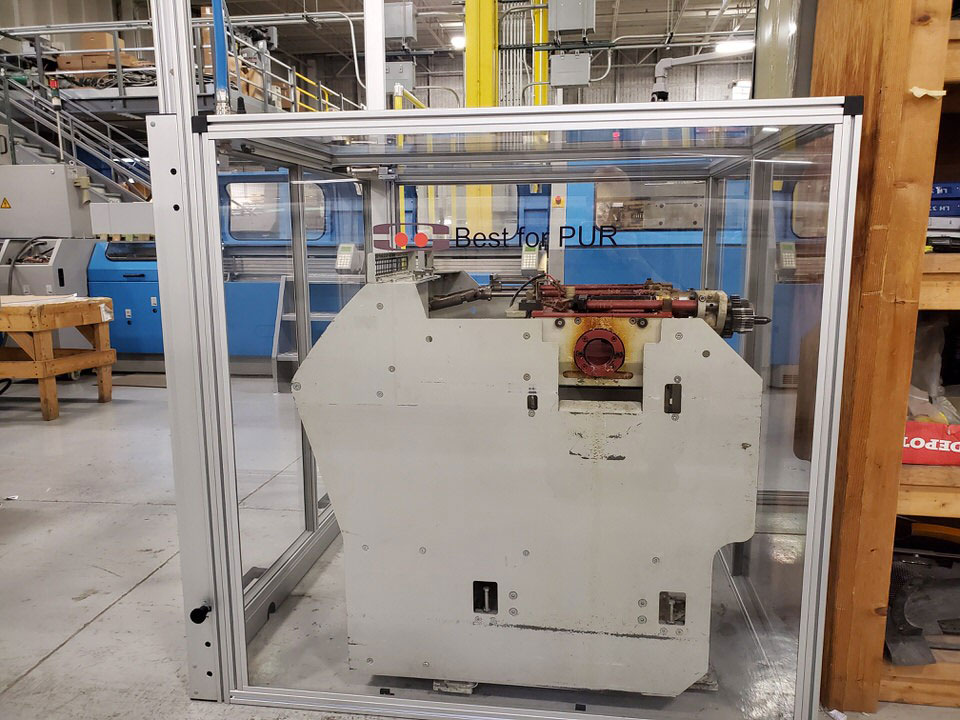

Your perfect binder offers enough space for efficient processes.

Our XXL hood guarantees maximum flexibility. Easy change of adhesives and straight forward PUR preservation – simply ideal.

For more details and information please download our leaflet in PDF format …

… or watch our videos on YouTube:

Best for PUR videos:

Glue preservation German:

https://youtu.be/cmOkf7_c0pE

Glue preservation English:

https://www.youtube.com/watch?v=4Sv9Yelp4YA

User Story Bookbinding Convention 2011 (German):

https://www.youtube.com/watch?v=D65ZibZbkpM